How to Train Your Team on Operating a Strapping Machine Safely

How to Train Your Team on Operating a Strapping Machine Safely

Blog Article

Letting loose the Prospective of a Strapping Device in Enhancing Your Procedures

A strapping device could be the solution you have actually been searching for if you're looking to boost your product packaging efficiency. These machines can lessen hands-on labor while ensuring your items are firmly packaged. With different options offered, discovering the best fit for your procedures is vital. Just how do you select the best one, and what benefits can you actually anticipate? Let's discover the opportunities together.

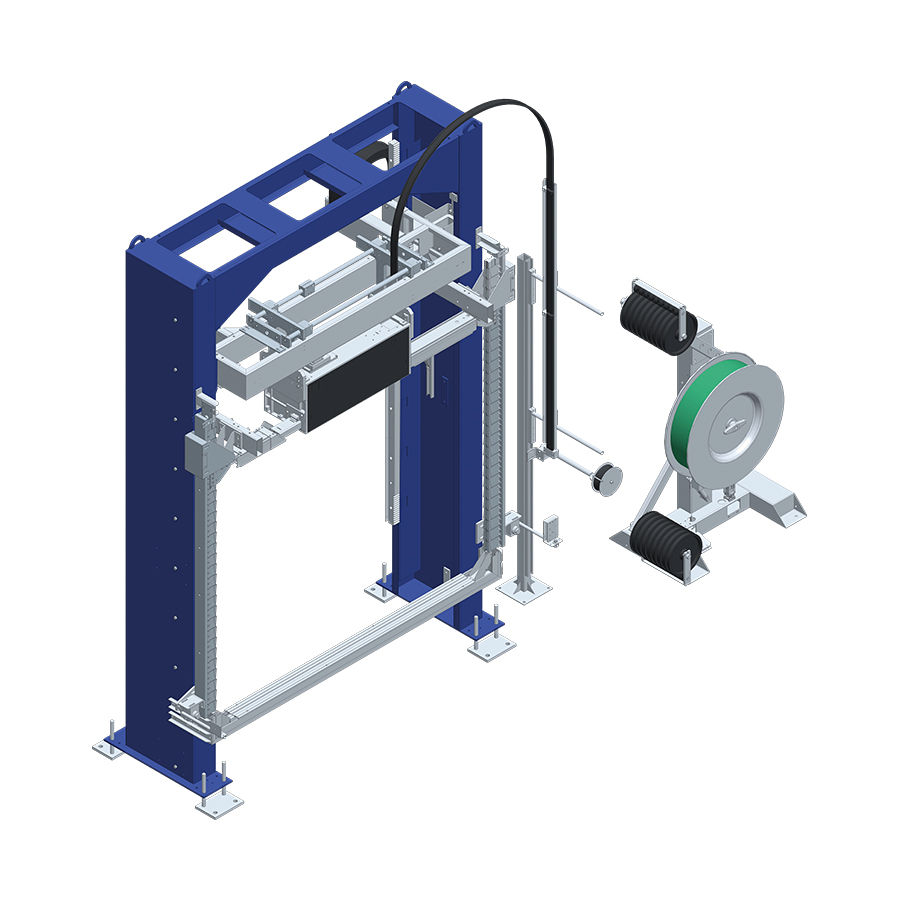

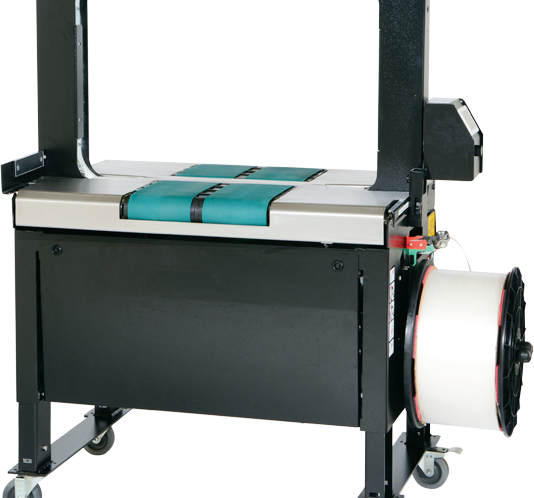

Understanding the Fundamentals of Strapping Machines

Strapping makers are essential tools in product packaging and logistics, made to protect products for safe transportation. These machines use various products, like polypropylene or polyester straps, to pack items together (Strapping Machine). You'll discover that strapping machines come in different types, consisting of guidebook, semi-automatic, and totally automatic versions, each matched for specific operational needs.Understanding just how these equipments job is crucial for maximizing your operations. They apply stress to the strap prior to securing it, making certain a limited fit that keeps your items safeguard throughout handling and delivery. Acquainting yourself with the elements, such as the tensioning device and securing technique, can help you select the ideal maker for your organization

Secret Benefits of Making Use Of a Strapping Machine

When you invest in a strapping equipment, you're not just improving your packaging process; you're likewise improving efficiency and reliability. These makers enable quicker strapping, decreasing manual labor and lessening the danger of errors. You'll discover a significant decline in time spent on packaging, enabling your team to concentrate on other critical tasks.Moreover, strapping equipments supply constant stress and protected packages, which aids avoid damages during transportation. This dependability leads to fewer returns and enhanced client contentment. In addition, using a strapping equipment can conserve you cash in the long run by lowering material waste and decreasing labor costs.Lastly, they're flexible adequate to manage various package sizes and materials, making them a valuable possession in any kind of procedure. Accepting a strapping maker suggests you're buying a much more structured, reliable, and reliable technique to packaging.

Types of Strapping Machines Available

When it concerns strapping devices, you've got options. You can pick in between hand-operated strapping devices for hands-on control or automatic strapping systems for effectiveness. Each kind has its very own benefits, making it crucial to choose the appropriate one for your demands.

Guidebook Strapping Machines

Although several product packaging solutions exist, hands-on strapping devices attract attention for their simpleness and effectiveness. These makers are ideal for tiny to medium-sized procedures where portability and flexibility are vital. You'll find them simple to utilize, calling for very little training. With a hands-on strapping maker, you can swiftly secure plans utilizing polypropylene or polyester bands, ensuring your items remain undamaged during shipping.They supply an affordable service without giving up top quality, making them ideal for organizations on a spending plan. Plus, manual strapping equipments are compact and can suit limited areas, allowing you to enhance your workflow. Whether you remain in a storehouse or a little workshop, these devices can greatly boost your product packaging process, making your operations more trusted and effective.

Automatic Strapping Equipments

Have you considered exactly how automated strapping systems can transform your product packaging procedures? These machines offer effectiveness and precision that manual approaches just can not match. With options like completely automated, semi-automatic, and high-speed strapping systems, you can pick the ideal fit for your manufacturing needs. Totally automated systems streamline the whole process, requiring marginal driver intervention. Semi-automatic equipments, while still reliable, permit a little bit more control. High-speed systems cater to high-volume procedures, guaranteeing fast and trusted strapping. By integrating these systems, you'll not only lower labor expenses yet likewise improve packaging high quality. Claim goodbye to inconsistent strapping and hello to consistent, secure bundles that improve your operational efficiency and speed. It's time to step up your game with automatic strapping services!

Factors to Think About When Selecting a Strapping Device

Picking the ideal strapping machine can considerably enhance your product packaging performance, so it's essential to think about a number of key elements prior to making a decision. Initially, consider the kind of products you'll be strapping. Various devices are created for paper, plastic, or steel strapping, so pick one that fulfills your needs.Next, consider the rate and quantity of your operations - Strapping Machine. If you're collaborating with high volumes, an automated strapping equipment may be preferable, while a manual choice could be enough for smaller sized tasks.Don' t forget the machine's dimension and footprint. Make certain it fits your work space without impeding movement.Additionally, try to find functions like flexible stress and sealing methods to advertise flexibility. Finally, assess your budget plan, balancing upfront prices against long-term efficiency gains. By thinking about these factors, you'll make a more enlightened selection that lines up with your operational objectives

Exactly how to Integrate a Strapping Equipment Into Your Process

To successfully integrate a strapping equipment into your process, begin by reviewing your functional demands. This aids guarantee the device fits flawlessly into your existing procedures. When that's established, effective staff training will certainly be key to optimizing its performance and performance.

Analyzing Functional Demands

Incorporating a strapping device right into your workflow can significantly enhance efficiency and productivity. Examine your existing packaging process. Determine traffic jams where manual strapping slows you down. Take into consideration the volume of items you handle day-to-day and the specific demands for safeguarding those things. Assess the physical space offered for the maker to assure it fits seamlessly into your operation. Next, determine the sorts of products you utilize for strapping, as the equipment ought to fit them. It's additionally important to consider exactly how the maker will certainly connect with existing tools and workflows. By understanding these operational requirements, you can choose the right strapping machine that straightens with your objectives, inevitably leading to smoother procedures and enhanced outcome.

Educating Team Efficiently

While the intro of a strapping maker can improve your process, effective training for your staff is important to maximize its benefits. Beginning by giving hands-on demos to acquaint everybody with the machine's features and functions. Motivate your team to ask inquiries and share their problems. Create an user-friendly manual or quick-reference overview to enhance training and function as a resource. Schedule normal refresher courses to maintain skills sharp and address any updates or changes. In addition, appoint an advisor or knowledgeable operator to sustain new employee as they adapt. By buying your staff's training, you'll not just boost their confidence yet likewise enhance efficiency, guaranteeing the strapping machine ends up being an essential component of your operations.

Maintenance Tips for Optimum Strapping Device Efficiency

Maintaining your strapping maker is vital for ensuring constant efficiency and longevity. Begin by frequently checking and tightening any kind of loosened bolts or screws to avoid resonances that can create wear with time. Clean the device daily, removing dust and particles that can influence its efficiency. Lubricate moving parts as recommended in the manufacturer's manual, making sure smooth procedure and reducing friction.Monitor the strapping stress and adjust it according to your material specs, as inappropriate stress can lead to product damage or look at here now squandered products. Strapping Machine. In addition, inspect the strapping material for any type of indications of wear or damages, changing it as required to stay clear of disturbances in your workflow.Finally, schedule routine professional maintenance to capture potential problems prior to they become major problems. By complying with these upkeep tips, you'll keep your strapping device running smoothly, boosting your operations and lengthening its life-span

Real-World Success Stories of Strapping Equipment Execution

After guaranteeing your strapping equipment runs effectively, it's time to explore how companies have actually efficiently utilized this innovation. Take, for instance, a packaging company that fought with irregular strapping. After carrying out a contemporary strapping device, they saw a 30% increase in throughput and a significant reduction in product waste.In another circumstances, a furniture supplier made use of strapping makers to protect products for delivery. This not just accelerated their packing procedure however likewise reduced damages during transit, bring about better customers.Similarly, an e-commerce business incorporated strapping makers into their operations, allowing them to effectively bundle products and reduce labor costs.These success tales highlight exactly how investing in a strapping machine can drastically improve your functional effectiveness, cut prices, and improve customer fulfillment. By gaining from these examples, you can better visualize just how this technology can transform your very own business procedures.

Frequently Asked Concerns

Can a Strapping Device Deal With Various Materials and Sizes?

Yes, a strapping equipment can handle different materials and dimensions. You'll find versions designed to fit various band sizes and thicknesses, guaranteeing convenience for your packaging needs and improving effectiveness in your procedures.

What Is the Ordinary Lifespan of a Strapping Machine?

The average life expectancy of a strapping maker commonly ranges from 5 to ten years, relying on use and upkeep. Routine maintenance and appropriate treatment can assist you optimize its longevity and efficiency over time.

Are There Safety Functions in Modern Strapping Machines?

Yes, modern strapping machines come with various safety and security attributes, like emergency situation stop buttons, safety guards, and sensing units that stop operation when parts are inaccurately positioned. These improvements help guarantee your security while utilizing the tools.

Just How Much Training Is Needed for Operators?

You'll require very little training for operators, usually a couple of hours to a number of days, depending upon their experience. Most machines feature straightforward user interfaces, making it simple for your team to adjust swiftly.

Can Strapping Machines Be Leased Rather Than Acquired?

Yes, you can lease strapping devices as opposed to acquiring them. Leasing often gives versatility, minimizing upfront costs while allowing you to upgrade tools as required. It's a smart alternative for managing your functional budget effectively. You'll locate that strapping makers come in different kinds, consisting of guidebook, semi-automatic, and completely automatic designs, each suited for specific functional needs.Understanding exactly how these equipments work is essential for maximizing your workflow. When you spend in a strapping device, you're not simply boosting your packaging procedure; you're also enhancing effectiveness and reliability. You can pick between hand-operated strapping devices for hands-on control or automated strapping systems for effectiveness. If you're functioning with high volumes, an automated strapping maker might be much more suitable, while a hands-on option can be adequate for smaller tasks.Don' t neglect regarding the device's dimension and More Bonuses footprint. After carrying out her latest blog a modern strapping maker, they saw a 30% rise in throughput and a substantial decrease in material waste.In another instance, a furniture supplier used strapping devices to safeguard items for shipping.

Report this page